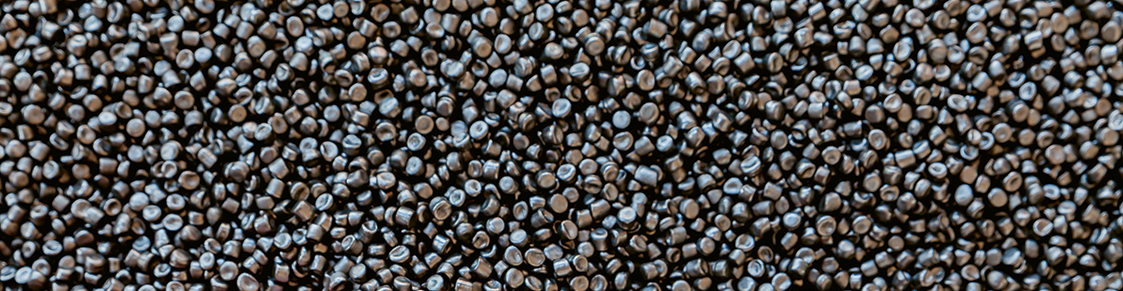

Upcycling with up to 80% recycled content

Recycled materials are often inconsistent and unpredictable. Therefore, while we do create compounds using recycled sources, we recognize that using 100% recycled content may not meet the standards for high-quality applications. This is why we focus on upcycling, developing compounds with up to 80% recycled content. The remaining 20% allows us to fine-tune our compounds to meet customer specific requirements.

Various directions to reduce your carbon footprint

In our EcoForte range, we offer compounded products that can help transition towards a more sustainable future. Our formulations include compounds made from biobased materials, biodegradable polymers, and recycled materials. We have a variety of options available and can customize solutions to meet our customers’ specific needs.

Supporting the transition towards a circular economy

Our upcycled compounds are developed on a case-by-case basis depending on the plastic conversion process, recycling stream, and desired property profile. We usually accomplish this with a closed-loop mindset, collaborating with various parties in the value chain to produce the most efficient sustainable compounds. Our role is crucial in formulating and manufacturing semi-finished products to create the best possible sustainable alternative, but our main focus is on our expertise: Compounding. Therefore, we are not a recycler, but we create high-value compounds for the future by enhancing recycled streams with our knowledge.

Upcycling

When working with recycled-based content, it is common that you need to develop dedicated formulations for each application. We develop these formulations together with our customer base. However, we do have some standard materials in our portfolio that are developed for different processing techniques, such as injection moulding, extrusion, and 3D printing. We provide glass fibre-based compounds where we have optimized all potential properties for short glass fibre reinforced compounds. Initially focused on virgin-based blends, we have managed to extrapolate this towards upcycled compounds as well, providing the optimal balance of post-consumer recycled streams with glass fibres. This offers yet another option to create the optimal upcycled polymer compounds.

Polyolefins as stepping stone

Although we aim to develop compounds using various base materials, we are unable to do everything. Our initial focus is on developing upcycled compounds from mechanically recycled polyolefin streams. With our extensive experience in polyolefin compounding, we can create specific solutions for a variety of applications and processing methods, all designed to meet the specific needs of our customers. We produce upcycled compounds from both post-industrial (PIR) and post-consumer (PCR) streams.

Sustainable Compounding

With a commitment to sustainability at the forefront, we strive to surpass environmental standards and work closely with customers to co-create eco-friendly compounds. As a prominent figure in the industry, our goal is to pioneer sustainable innovation and create compounds for the future. We continuously push ourselves towards a more sustainable future.